- 1976

- 1982

- 1983

- 1989

- 1992

- 1993

- 2004

- 2005

- 2008

- 2010

- 2011

- 2012

- 2013

- 2014

- 2015

- 2016

- 2017

- 2018

- 2019

- 2020

- 2021

- 2022

- 2023

- 2024

-

1976

Set up heat pipe research group

-

1982

Set up heat pipe research office

-

1983

Set up Nanjing Heat Pipe Technology Development Center

-

1989

Set up heat pipe research school

-

1992

Set up heat pipe technology development and research

-

1993

Establish Jiangsu Shengnuo Heat Pipe Group Co., Ltd

-

2004

Establish Jiangsu Shengnuo Heat Pipe Co., Ltd

-

2004

Establish Nanjing Shengnuo Heat Pipe Co., Ltd

-

2005

Sunpower Group went to public

-

2008

The company obtained provincial high-tech enterprise

-

2

The company obtained the engineering design qualification of "Chemical, Petrochemical and Pharmaceutical Industry (Chemical engineering) Grade B"

-

5

Set Nanjing Shengnuo Engineering design and research

-

3

Awarded "2011 Jiangsu Province Intellectual Property Management

-

6

Nanjing Shengnuo successfully obtained pressure vessel

-

12

Trademark on NSN products such as heat pipe, heat pipe exchanger, finned tube etc. recognized as famous trademark by the province

-

3

Awarded as “Jiangsu energy-saving service company”

-

4

Approved by the Ministry of Science and Technology as the National Science and Technology Support program "Metallurgical energy-saving key Technology

-

5

Approved by the Ministry of Science and Technology as the international cooperation project "Joint Research and Development of Key Technologies for energy Recovery and By-product comprehensive Utilization of yellow

-

11

The company's first supplier conference "2012 Annual Supplier Congress of Sunpower Group Nanjing Shengnuo Heat Pipe Co., Ltd." was successfully held in Nanjing Hongqiao Hotel

-

4

Successfully passed the review of pressure pipeline design certificate renewal

-

9

Successfully passed the ISO9001 quality management system certification renewal review, ISO14001 environmental management system certification and OHSAS18001 occupational health and safety management system certification

-

10

Successfully passed the review of the certification renewal of class B waste heat boiler manufacturing

-

12

Successfully passed the safety production standardization secondary enterprise audit

-

5

The mechanical industry standard "General Technical conditions for Complete sets of Equipment for waste heat Recovery and Utilization of low and medium

-

8

The company signed an order with ExxonMobil Refinery to develop the US market successfully

-

9

The transformation project of scientific and technological achievements in Jiangsu Province undertaken by the company "Research and Development and Industrialization of high temperature alternating, high dust, corrosive flue gas

-

9

The company passed the certification review of high-tech enterprises in Jiangsu

-

9

On September 16, 2014, the company was supported by the provincial strategic emerging industries energy-saving environmental protection project government special fund project, and received a total of 3 million yuan of support funds

-

5

Passed the certification renewal review of famous trademark

-

12

Trademark on NSN products such as heat pipe, heat pipe exchanger, finned tube etc. recognized as famous trademark by the province twice

-

12

Trademark of SHENGNUO heat pipe, heat pipe exchanger, finned tube and other products(service) recognized by the city as famous trademark

-

2

The company passed the verification of 2014 International cleaner production secondary enterprise organized by the Municipal Economic and Information Commission and the Municipal Environmental Protection Bureau

-

12

The company's product "Shengnuo heat pipe heat exchanger" once again recognized as a provincial famous brand product

-

3

The Company undertook the first MGGH project

-

4

The company undertaken the first set of heat pipe GGH in petrochemical heating furnace desulfurization island in China

-

4

The company undertook the first set of low temperature waste heat recovery project in self-supply power plant unit

-

7

The company won the Gulou District intellectual property work advanced collective honor

-

7

The company obtained the qualification of "Abiding by contract and being trustworthy" by the Municipal Administration for Industry and Commerce in 2015, again

-

8

The company participated in the preparation of the industry standard "Engineering Technical conditions for Heat Pipe Preheater for petrochemical tube furnaces"

-

8

The company again obtained AAA credit rating qualification

-

9

The company's enterprise engineering technology center was rated as excellent in the acceptance and performance evaluation of Jiangsu Enterprise Engineering

-

10

The company successfully passed the ISO9001 quality management system certification review and ISO14001 environmental management system certification and OHSAS18001 occupational health and safety management system certification

-

10

The company won the 2016 Provincial Policy guidance Program (International science and Technology Cooperation) project

-

10

The company successfully co-organized the 2016 National Chemical Machinery Academic Conference, Chairman Guo Hongxin as a special invited expert to attend and made a speech

-

10

Shengnuo "heat pipe, waste heat boiler, low temperature economizer" again won the qualification of provincial quality product

-

11

The Company’s first management service project started

-

11

The first unit of company’s first set of low temperature waste heat recovery project in self-supply power plant unit went into operation smoothly

-

11

The 2.8MT/a CO incinerator and waste heat boiler B furnace project of Dalian West Pacific Petrochemical Co., LTD., undertaken by the company, was put into operation successfully

-

11

Chairman Guo Hongxin was elected representative of Gulou District People's Congress

-

11

The heat pipe workshop of the company's equipment manufacturing plant passed the clean production audit and acceptance

-

11

The national science and technology support project undertaken by the company passed the acceptance

-

12

The company passed the review of safety standardization secondary enterprise

-

4

The Company passed smoothly the pressure pipeline GC2 level design

-

8

The registered capital of the company increased to 30 million yuan

-

8

company again obtained AAA credit rating

-

10

The heat pipe workshop of the company's equipment manufacturing plant received the sewage discharge permit smoothly

-

12

The provincial strategic emerging industries supporting energy conservation and environmental protection industry project passed the acceptance

-

12

The company again obtained the qualification of high-tech enterprise

-

12

The company has completed the certification renewal of A boiler parts and the upgrading of B grade waste heat boiler to B grade boiler

-

3

The company obtained the qualification of "Class A Enterprise of Green Comprehensive Evaluation of Non-chemical enterprises" evaluated by the Chemical Industry Transformation and Development Management Office of Jiangbei New District

-

4

The company's equipment manufacturing factory passed ASME qualification examination

-

4

A group of 10 customers from Hyundai Group visited Nanjing Shengnuo Heat Pipe Co., Ltd

-

4

The Company passed successfully the design certification renewal of pressure vessel D1 and D2

-

4

The first set of flue gas cooler in sintering denitrification process undertaken by the company was successfully delivered

-

5

The company won the honorary qualification of provincial enterprise technology center again

-

5

The Company undertook the first sintering heat exchanger to eliminate white flue plume.

-

6

The Party branch of the company and the central gate street Quanye Road community Party station jointly carried out "in-service party members into the community, clean the home I first" Party members theme Day activities

-

6

Successfully undertook white flue plume elimination project in Taiwan, realized the zero break in Taiwan province.

-

7

The company undertook the first set of petrochemical two-phase flow heat exchanger project -- Fujian Refining and Chemical project

-

7

The company held 2018 semi-annual summary and management review meeting

-

9

The company undertook the project of Hebei Zongheng Group Fengnan Iron and Steel Co., LTD. Project

-

10

The company undertook Meigang 4# sintering waste heat boiler successfully put into operation and connected to the grid

-

12

The Company equipment factory passed Jiangbei New District double control acceptance

-

6

The acetic acid tail gas recovery system of Hengli Petrochemical acetic acid unit contracted by the company and Zhongshengyuan been put into operation smoothly

-

8

The clean coal gasification project of China Wuhuan contracted by the company was delivered smoothly

-

10

The company obtained Xinjiang Midong power plant commendation letter

-

10

The company's Hyundai Steel project delivered smoothly

-

10

The Company obtained commendation letter from Datang Changchun third thermal power plant

-

6

Party branch of the company completed the election work

-

8

The company won the bid of Chongqing Iron and steel sintering waste heat power project

-

12

Shengnuo Jiangning heat pipe workshop passed smoothly through the check and acceptance of clean production

-

1

Shengnuo Heat pipe Party branch year-end summary conference held smoothly

-

1

The company held the 2020 annual briefing meeting

-

2

The company held 2020 annual commendation and award conference

-

2

The company held the deployment meeting of 2021 target achievement measures

-

4

The company again recognized as high-tech enterprise

-

5

The company's pressure pipeline design qualification renewal work been successfully completed

-

6

The company's class B boiler installation and construction certification successfully obtained

-

6

The Company’s Chongqing iron and steel sintering waste heat power generation project got praised

-

7

The liquid methionine heat exchanger contracted by the company was delivered smoothly

-

7

The company held the 2021 annual management review and work summary meeting of the first half year

-

9

The company successfully passed the external audit of quality, environment, occupational health and safety management system

-

11

Dr. Guo Hongxin, Party Secretary and Chairman of Sunpower Technology Group, visited Baosteel Zhanjiang Steel Group

-

11

The company was given a silk banner by China Resources Power (Changshu)

-

12

The company's 2021 annual summary meeting was successfully held

-

1

The company led the development of group standard"Technical specification for engineering of separated heat pipe exchangers" officially released

-

1

The company honoured with "Jiangsu Province enterprise of Abiding by Contract and Being Trustworthy"certificate

-

1

The company held 2021 annual commendation award and lucky draw for the Spring Festival

-

2

Nanjing Gulou District CPPCC chairman, Party secretary Dong Wei visited the company for inspection and guidance

-

2

Shengnuo Party branch year-end summary meeting was successfully held

-

3

The company's 2022 target responsibility signing ceremony was successfully completed

-

5

The company's Panzhihua Dongfang titanium flash dry waste heat recovery project won the owner's silk banner

-

5

The provincial engineering technology center under the company passed the performance evaluation

-

6

The company successfully held skills competition

-

7

The company held a review meeting for the first half of 2022

-

10

The company successfully passed the third-party re-certification audit of quality, environment and occupational health and safety

-

10

Company’s "Technical specification for engineering of separated heat pipe exchangers " won first prize of the municipal standard excellent cases

-

10

The subsidiary of the company, Jiangsu Shengnuo Energy Saving Technology Engineering Co., Ltd. was established in Yizheng City

-

11

Sunpower Technology’s EMC project of Meigang 4# sintering low temperature waste heat recovery for power generation successfully connected to the grid

-

11

The company won the honorable qualification of Jiangsu Province special fine new small and medium enterprises

-

12

The company increased its capital by 50 million yuan, and the registered capital reached 80 million yuan

-

2

"Low-temperature heat exchange island technology of blast-furnace gas boiler" passed the identification of new technology and new product by Jiangsu Industry and Information Technology Department

-

3

The signing ceremony of the company's 2023 target responsibility letter was successfully completed

-

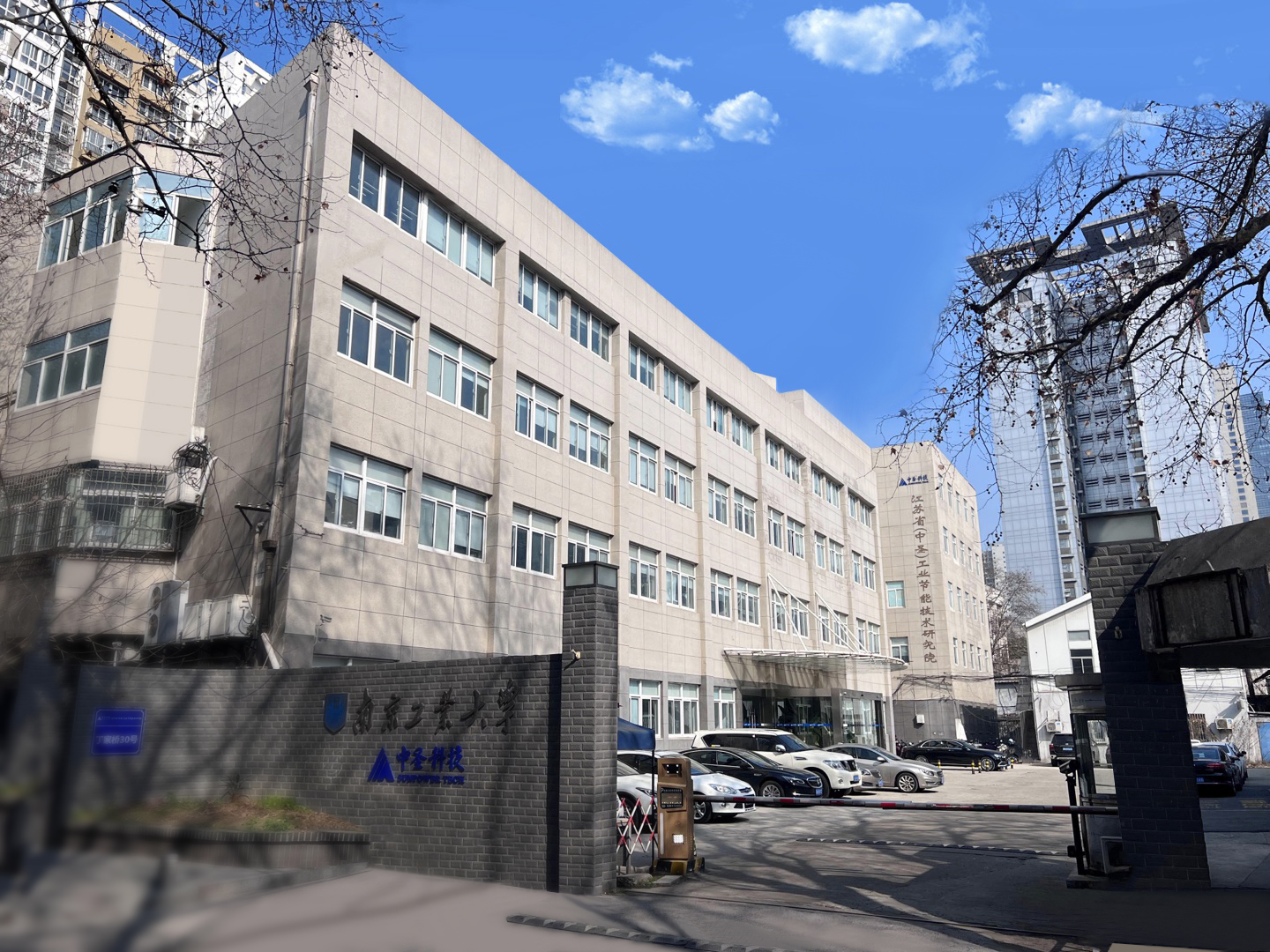

4

Jiangsu Shengnuo Company relocation ceremony was successfully held

-

5

Party Branch of Nanjing Shengnuo Heat Pipe, Sunpower Tech(later renamed as the Sixth Party Branch of Sunpower Tech) was officially established

Company's pressure vessel design, manufacturing renewal work successfully completed

-

8

"Low-temperature heat exchange island technology of blast-furnace gas boiler" was selected into the Jiangsu Province key promotion and application of new technology and new product catalogue;

"Carbon steel - water gravity heat pipe" products won the "Jiangsu quality" certification -

9

Company successfully passed the third-party re-certification audit of quality, environment and occupational health and safety

-

11

Company passed the high-tech enterprise identification again

-

2

Company held 2023 year-end commendation and 2024 New Year celebrating party

-

3

The signing ceremony of the company's 2024 target responsibility letter was successfully completed

-

5

Company obtained ASME "U" & "S" steel seal qualification certification